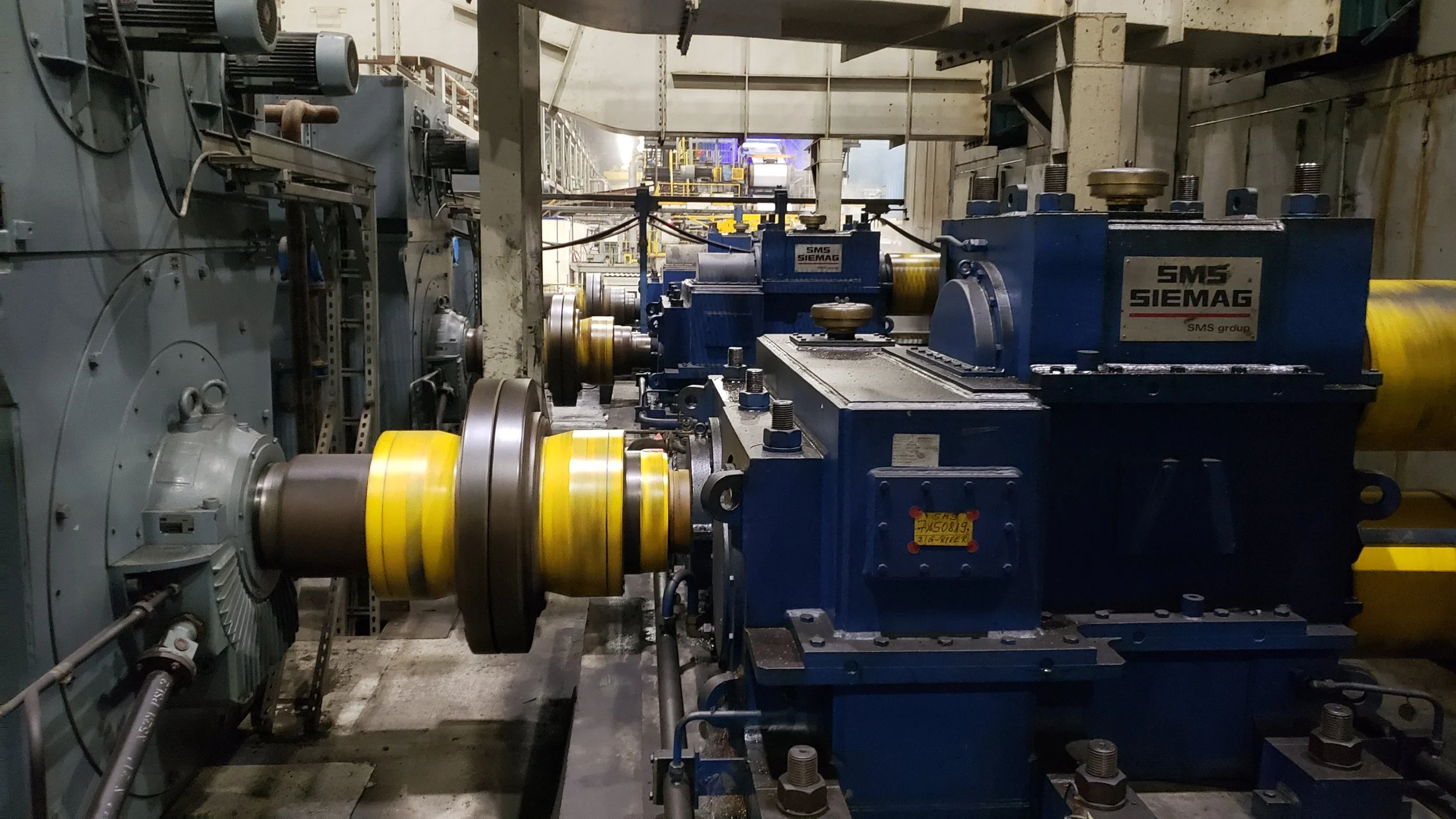

Predictive Maintenance for Every Industry.

Our

Services

-

Vibration Analysis

On Site Route based or Remote, Wireless Monitoring

-

Balancing

Dynamic in situ balancing

-

Infrared

Electrical and Mechanical IR Thermography

-

Specialty

ODS Modal Commissioning etc

Ready to Solve your Vibration Problem?

It all begins with filling out the contact form. A quick explanation of your problem and we will be in touch with you shortly with a plan to bring your equipment back into spec.

Only need to monitor 1 machine, we have a solution for you.

We focus on delivering the best service utilizing the newest technology. By keeping our overhead low we can offer the best US based service at a reasonable cost.

Why should you have a vibration analysis program? Because it's a powerful, cost-effective tool that helps to identify machinery problems early and avoid expensive failures. Here's how it saves money:

Prevents Unexpected Downtime

Unplanned downtime is often one of the most expensive problems in industrial operations.

Vibration analysis detects early signs of wear, imbalance, misalignment, or bearing failure—allowing companies to fix issues before they lead to costly breakdowns.

Reduces Maintenance Costs

Instead of relying on scheduled maintenance (which might be too early or too late), vibration analysis enables condition-based maintenance.

This means you only perform maintenance when it's needed, reducing labor, spare parts inventory, and service costs.

Extends Equipment Life

Early problem detection minimizes long-term wear and tear.

Addressing small issues before they escalate extends the operational lifespan of critical assets.

Improves Energy Efficiency

Faulty or misaligned machines often draw more power.

Correcting these issues through vibration analysis can lead to lower energy consumption, reducing utility bills.

Enhances Safety

Detecting and addressing equipment problems early helps prevent accidents that could harm employees or damage facilities.

Supports Data-Driven Decision Making

Vibration data gives actionable insights into asset health.

Maintenance managers can better plan capital expenditures and replacement schedules.

Finally:

By investing in vibration analysis, companies transition from reactive to proactive maintenance, significantly lowering operational risks and maintenance costs while improving reliability, safety, and profitability.