Wireless Vibration Monitoring

How it Works:

* Wireless Vibration Sensors: These small, battery-powered devices are equipped with accelerometers that detect and measure vibrations in multiple directions (X, Y, Z axes). They are mounted directly onto the machinery being monitored.

* Data Collection and Transmission: The sensors collect raw vibration data and processes this data. This processed data is then transmitted wirelessly on our network to a central monitoring system.

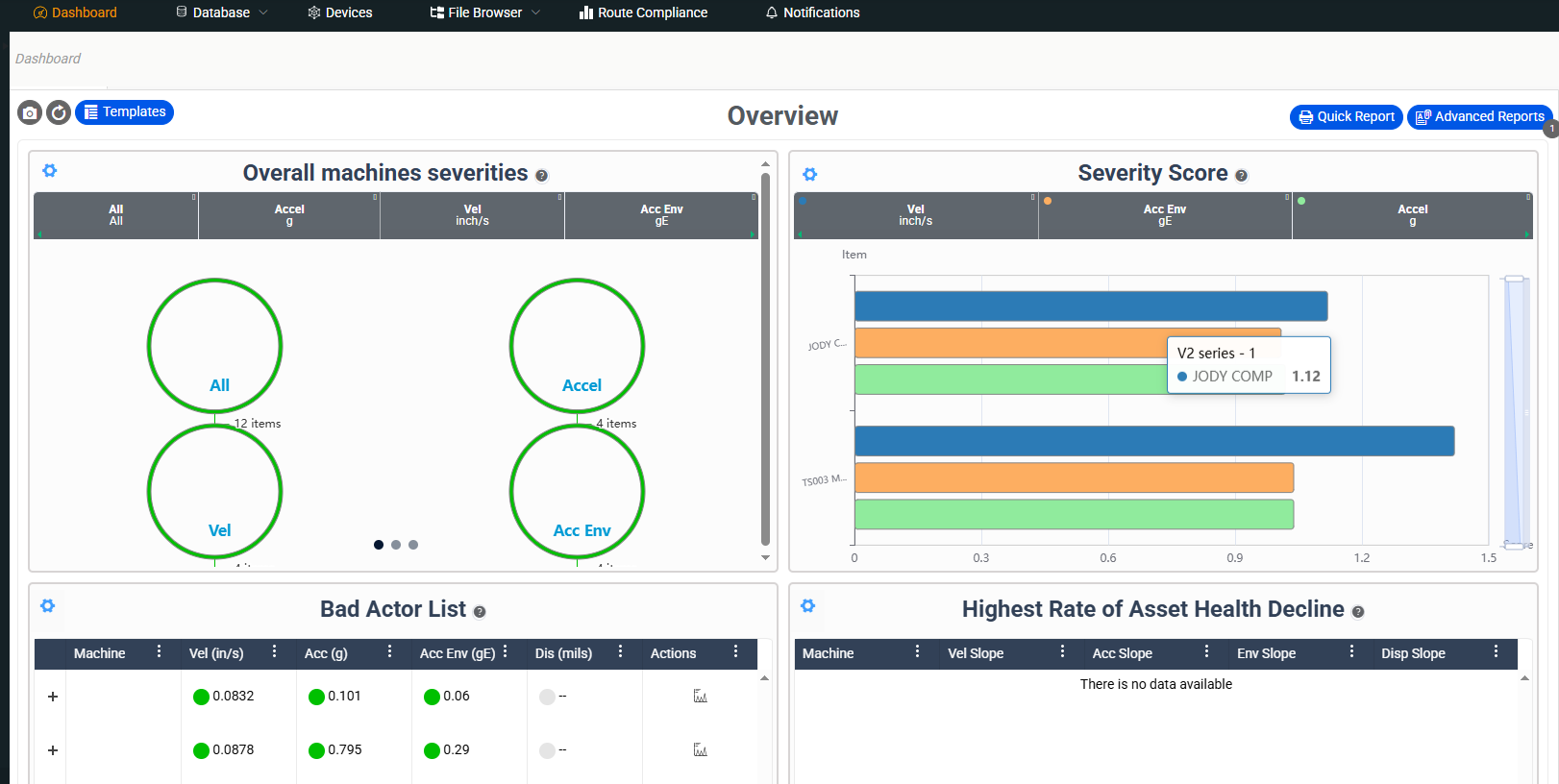

* Central Monitoring System: This system, a secure cloud-based platform, receives the data from all the sensors. It stores, analyzes, and visualizes the vibration information.

* Analysis and Alerts: Specialized software and algorithms are used to flag certainvibration patterns for review by a certified vibratio nanalyst. Every rotating piece of equipment has a unique "vibration signature." By establishing baseline data and setting alarm thresholds, the system can detect abnormal vibrations that may indicate issues like:

* Imbalance

* Misalignment

* Looseness in components

* Bearing damage

* Electrical faults

* Cavitation

* Lubrication problems

When unusual vibrations exceed the predefined thresholds, the system can trigger real-time alerts (e.g., via email) to maintenance personnel.

* Predictive Maintenance: The data collected from wireless vibration monitoring enables a predictive maintenance approach. Instead of waiting for a machine to break down (reactive maintenance) or performing maintenance on a fixed schedule (preventive maintenance), organizations can use the vibration data to anticipate problems and schedule maintenance only when it's genuinely needed. This minimizes unplanned downtime, reduces maintenance costs, and extends the lifespan of equipment.

Key Benefits of Wireless Vibration Monitoring:

* More frequent monitoring: Provides continuous insights into machine health.As opposed to the single data point collected monthly or quarterly during a route based program.

* Early Problem Detection: Identifies issues before they escalate into major failures.

* Reduced Downtime: Allows for proactive maintenance, preventing unexpected outages.

* Improved Safety: Enables monitoring in hazardous or hard-to-reach areas, reducing the need for personnel to enter unsafe environments.

* Increased Efficiency: Optimizes maintenance schedules and resource allocation.

* Cost Savings: Minimizes repair costs, extends equipment life, and reduces lost production due to downtime.

* Flexibility and Easy Installation: No complex wiring required, allowing for quick deployment and easy repositioning of sensors.

Wireless vibration monitoring is widely used in various industries, including manufacturing, oil and gas, transportation, and food processing, for assets like motors, pumps, fans, compressors, gearboxes, and more.

We can setup a wireless system for just 1 machine or an entire plant full. Please contact us below to be surprised at how affordable our system can be.

Our Equipment:

We Use Erbessd Phantom hardware for its rugged reliability. Customers have acess to the dashboard and data.

Coupled with EI Analytics and Digivibe software. This allows us to integrate route based collection with wireless programs. They have proven to be a reliable and fast system which means lower cost to the end user.